Wood is at the core of our collections. We work the finest of natural materials with passion, responsibility and creativity to create unique and fascinating wooden floors.

Discover the charm of wooden floors to furnish your spaces in harmony with the environment, well-being and beauty. Every detail is extraordinary and authentic: the warm and soft shades of colour, the original knots, the vibrant grains... We are inspired by nature, sustainable design trends and the variety of formats to enhance the distinctive qualities of each wood species, creating fascinating solutions for contemporary living. The processing, strictly carried out by hand by master artisans, makes our wooden floors unique and precious.

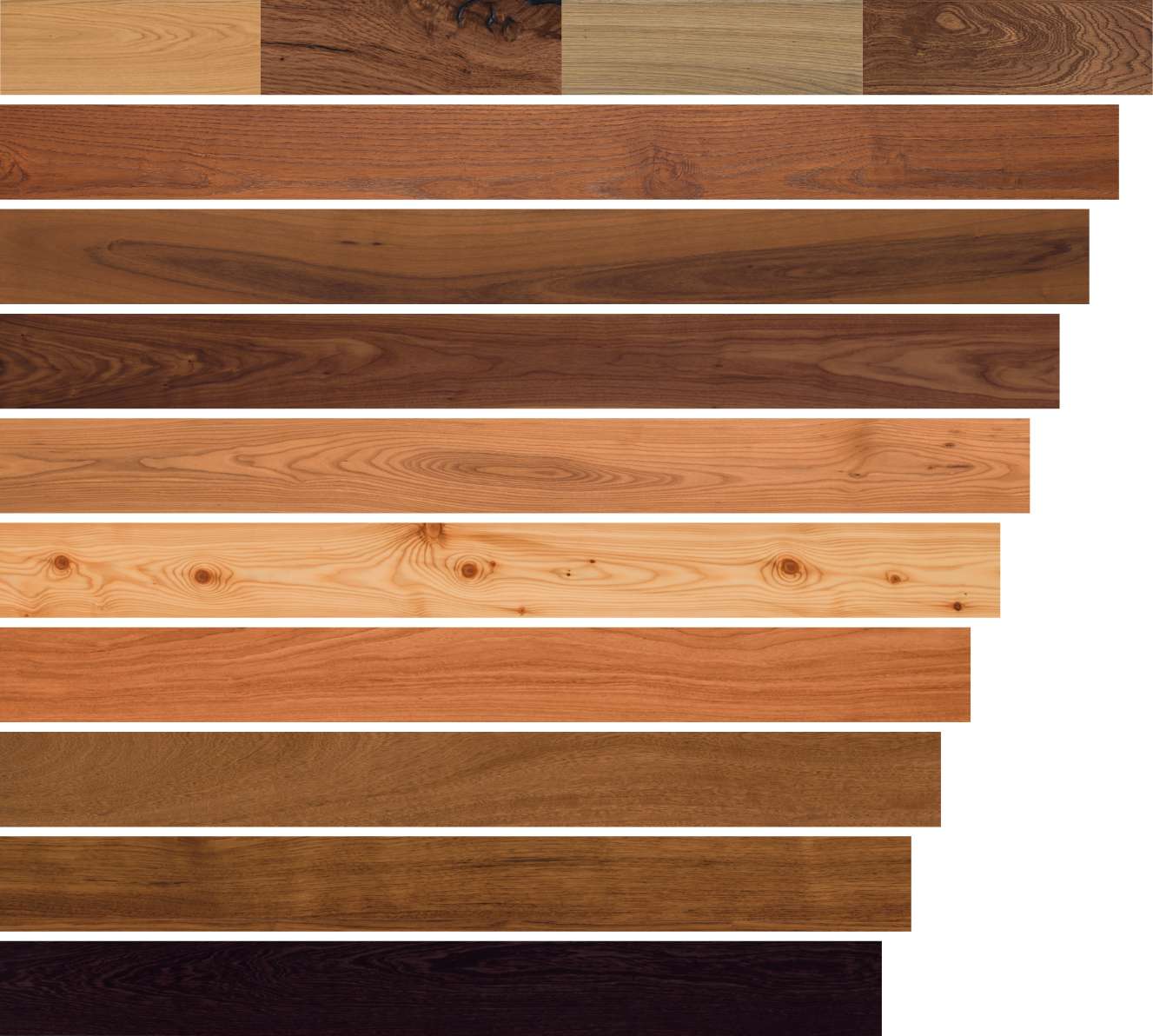

10 wood species

and over 600 finishes

Extraordinary customization possibilities.

The available combinations to create the parquet floor you have always dreamed of are innumerable.

Enjoy the freedom to customize every detail of your floor: from the type of wood to the sophisticated finishing, varnishing and oiling. Fall in love with the fabulous natural colours of traditional wood species or trendy exotic species. We have carefully selected the best, most beautiful and long-lasting varieties for you.

To make your floors even more original and evocative, combine the sought-after treatments that highlight textures, colour nuances, material sensations, natural or antique effects.

Wood essences

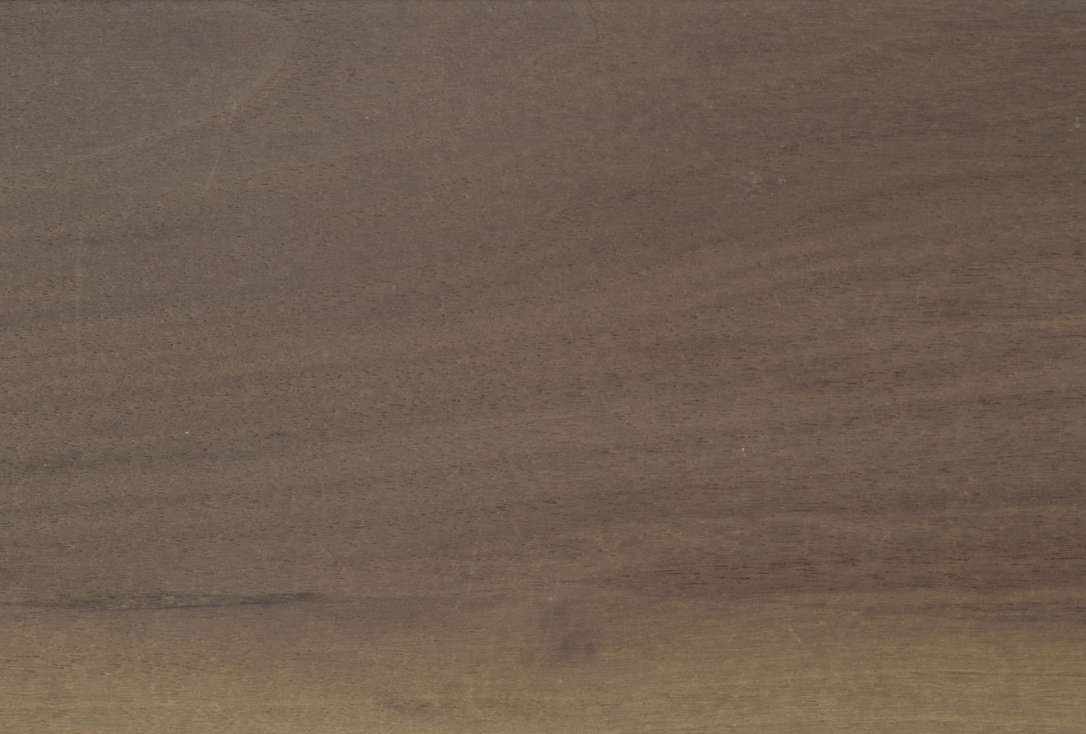

Afrormosia

Afrormosia varnished Evo

Afrormosia oiled / varnished

Afrormosia

Doussié

Doussié oiled / varnished

Doussié varnished Evo

Doussié

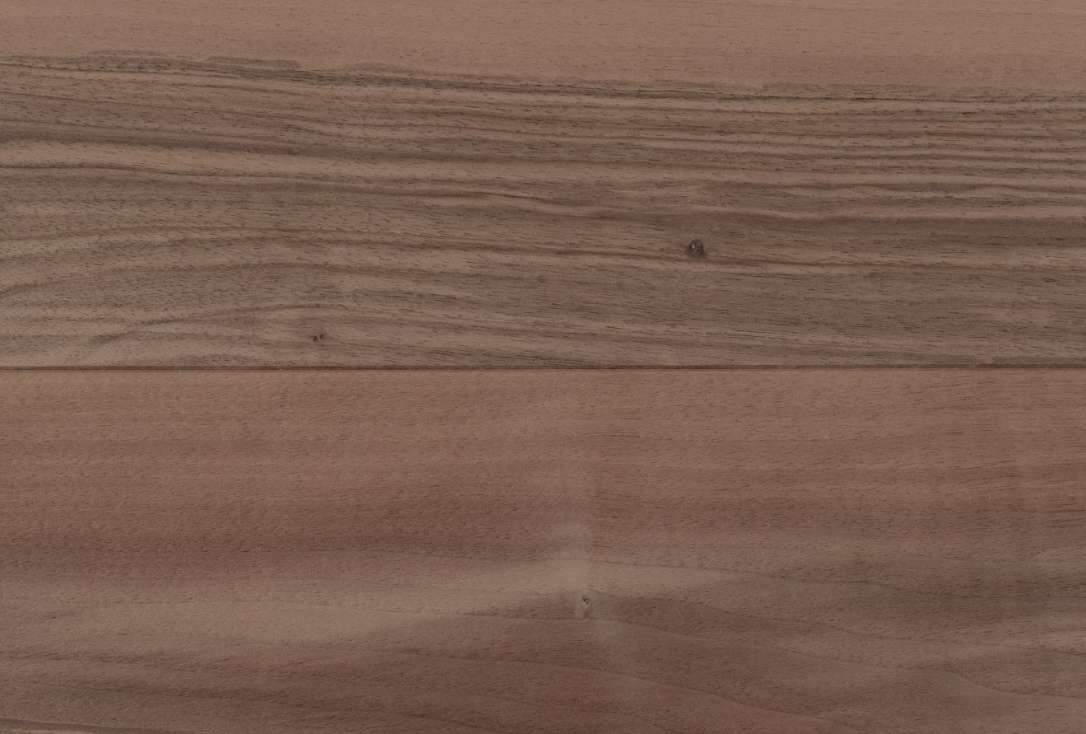

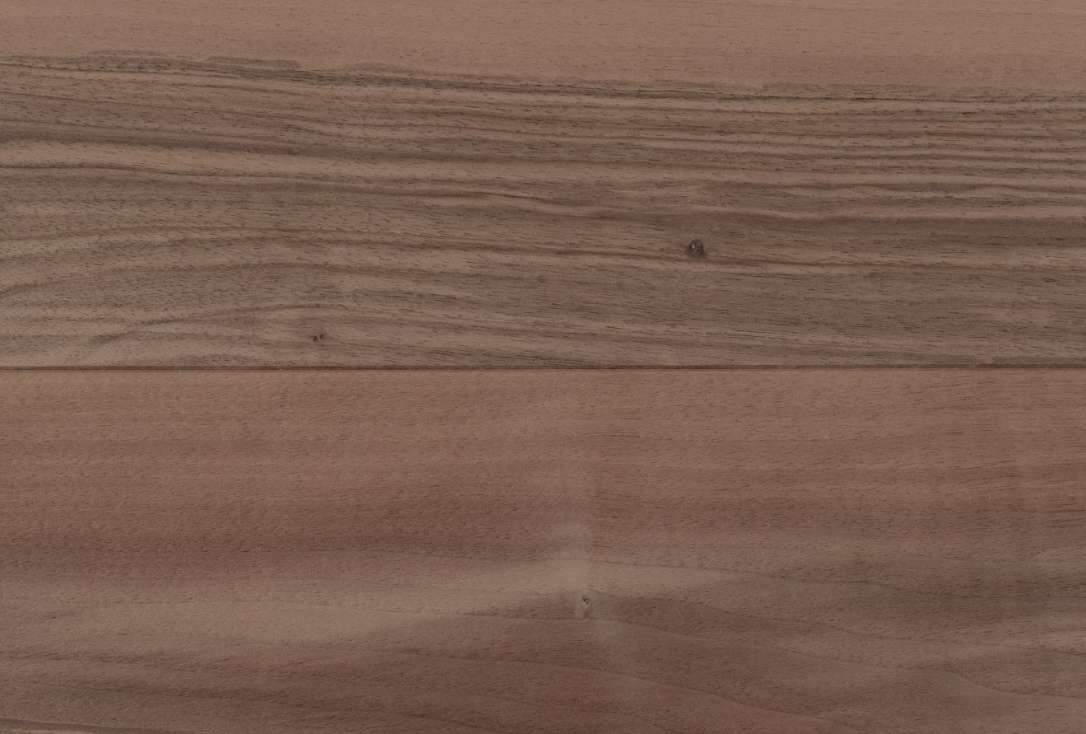

Ash

Ash oiled / varnished

Ash oiled Meduna

Ash oiled Meschio

Ash oiled Monticano

Ash varnished Evo

Ash varnished Bidoggia

Ash varnished Lia

Ash varnished Livenza

Ash varnished Negrisia

Ash

Iroko

Iroko oiled / varnished

Iroko varnished Evo

Iroko

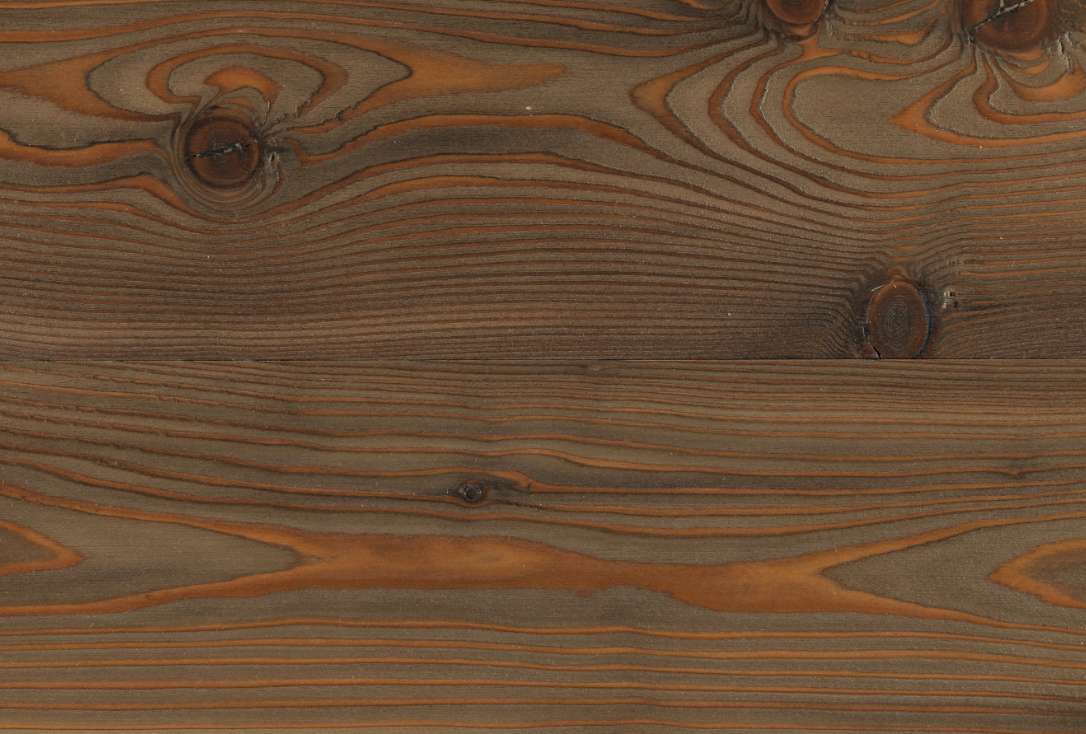

Larch

Larch oiled / varnished

Larch oiled Bormio

Larch Hills oiled Campiglio

Larch oiled Livigno

Larch oiled Stelvio

Larch Hills oiled Tonale

Larch varnished Evo

Larch varnished Cortina

Larch

American Walnut

American Walnut oiled / varnished

American Walnut tonalizzato

American Walnut Evo

American Walnut varnished E-Matt

American Walnut Uragano 2022

American Walnut

European Walnut

European Walnut oiled / varnished

European Walnut varnished Evo

European Walnut Argilla

European Walnut varnished E-Matt

European Walnut

American Elm

American Elm oiled / varnished

American Elm

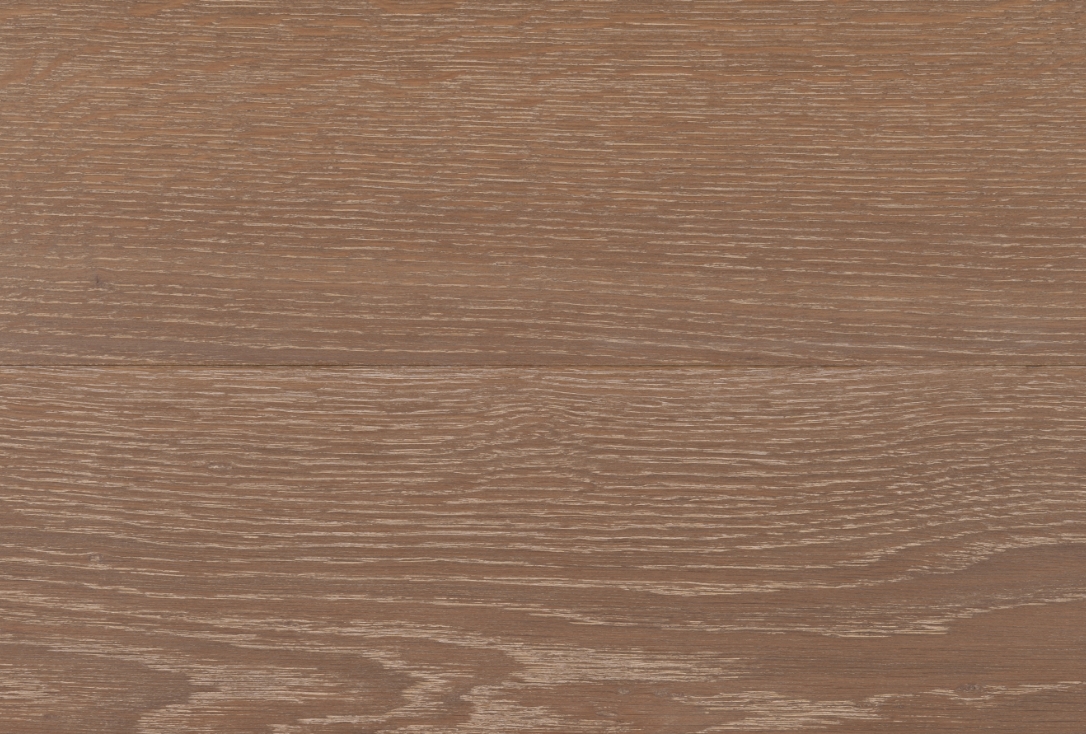

Oak

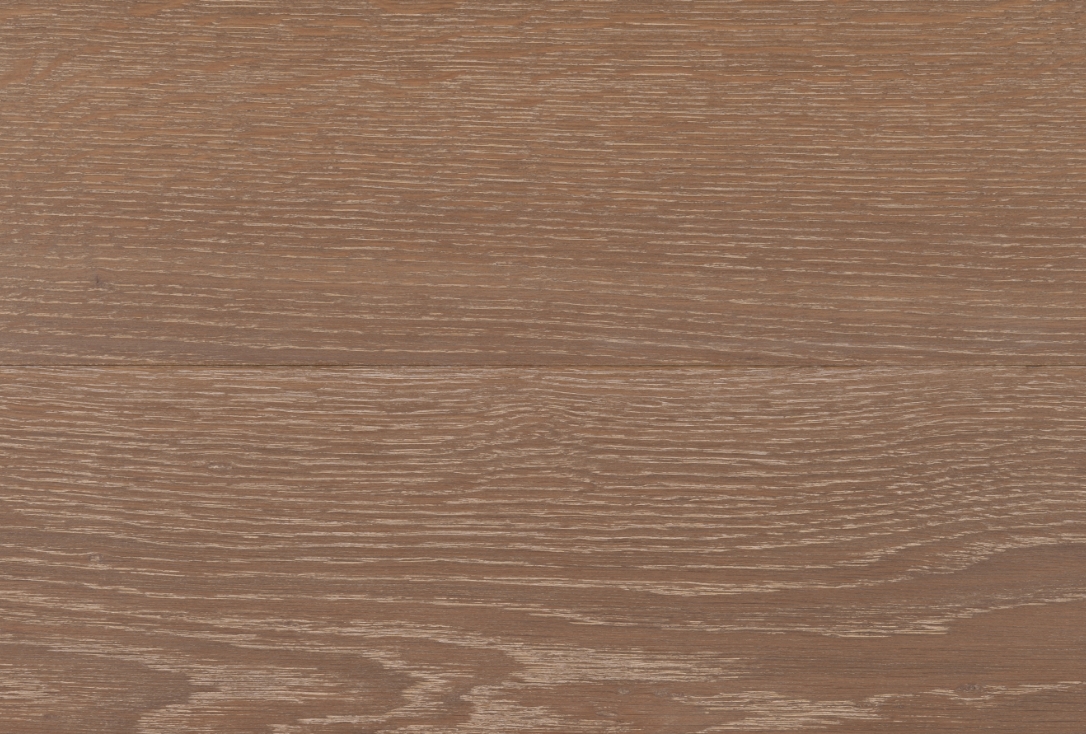

Oak oiled/varnished

Oak oiled Antracite 2023

Oak oiled Basalto

Oak oiled Dolomia 2023

Oak oiled Granito

Oak oiled Quarzo

Oak oiled Travertino 2023

Oak oiled velato bianco

Oak varnished decapé Cromo 2022

Oak varnished decapé Iridio 2022

Oak varnished decapé Litio 2022

Oak varnished Evo

Oak varnished E-Matt

Oak varnished Ambra

Oak varnished Corda

Oak varnished Creta

Oak varnished Cuoio

Oak varnished Ebano

Oak varnished Lava

Oak varnished Light

Oak varnished Neve

Oak varnished Pomice

Oak varnished Porfido

Oak varnished Tabacco

Oak varnished Metropolitan Chelsea

Oak varnished Metropolitan Oxford

Oak varnished Metropolitan Paddington

Oak varnished Metropolitan Soho

Oak varnished Metropolitan St. Paul’s

Oak varnished Metropolitan Trafalgar Square

Oak varnished Metropolitan Notting Hill

Oak varnished Metropolitan Westminster 2021

Oak varnished Eightcolor 8.1

Oak varnished Eightcolor 8.2

Oak varnished Eightcolor 8.3

Oak varnished Eightcolor 8.4

Oak varnished Eightcolor 8.5

Oak varnished Eightcolor 8.6

Oak varnished Eightcolor 8.8

Oak

Elite Oak

Elite Oak oiled Lisbona 2023

Elite Oak Hills oiled Nantes

Elite Oak Hills oiled Braga

Elite Oak oiled Dublino

Elite Oak oiled Madrid

Elite Oak oiled Vienna

Elite Oak oiled hand-planed / stone

Elite Oak varnished Havana

Elite Oak varnished Perth

Elite Oak varnished Toronto

Elite Oak varnished Evo / hand-planed / stone

Elite Oak varnished Bruges

Elite Oak varnished Parigi

Elite Oak varnished Porto

Elite Oak varnished Berlino

Elite Oak varnished Oslo

Elite Oak varnished hand-planed / stone

Elite Oak

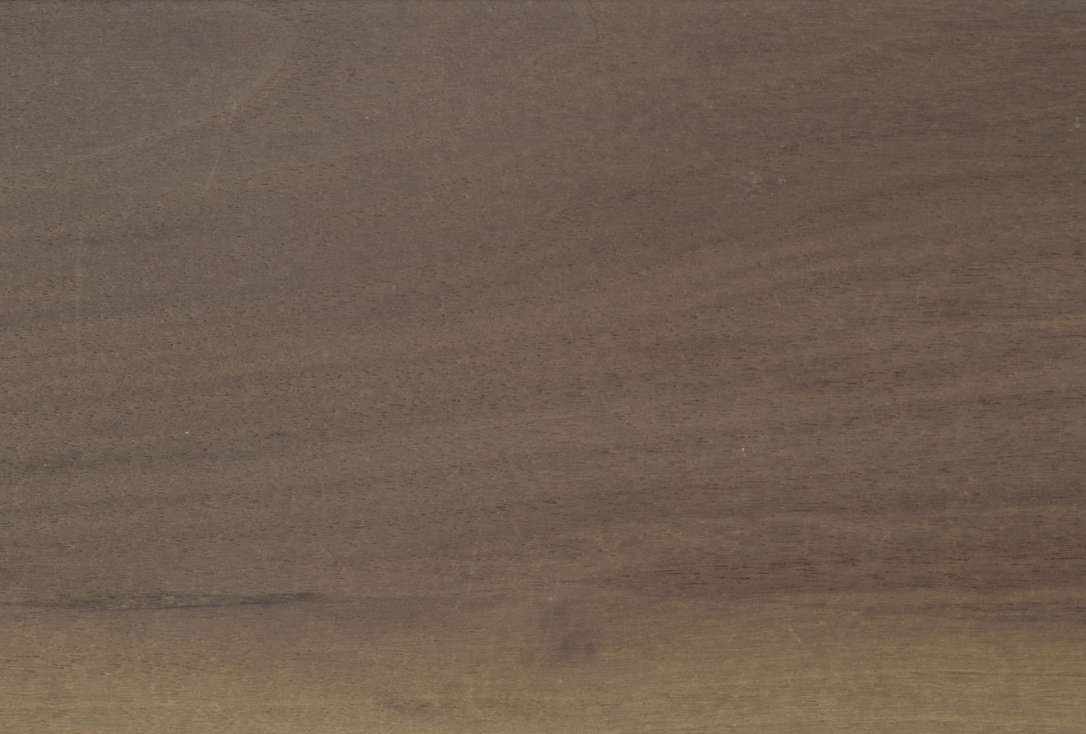

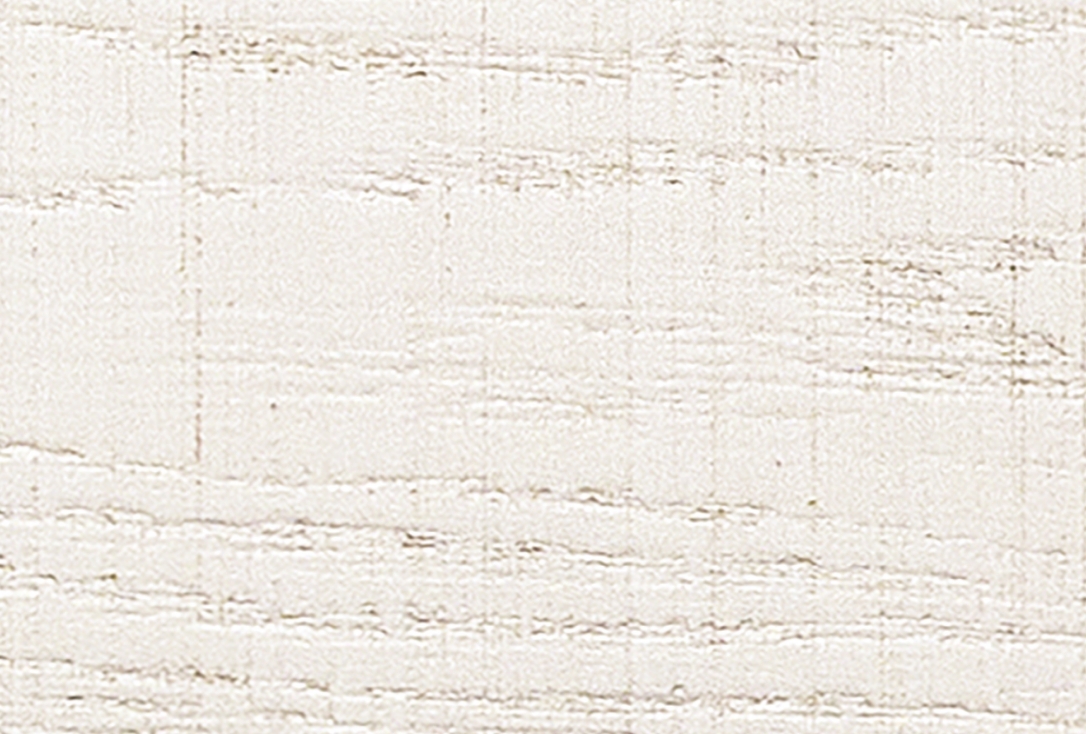

Materico Oak

Materico Oak varnished

Materico Oak varnished Evo

Materico Oak oiled waxed

Materico Oak oiled velato bianco

Materico Oak

Thermo Oak

Oak Thermo 130° oiled/varnished

Oak Thermo 130° velato bianco

Oak Thermo 130° varnished Evo / E-Matt

Oak Thermo 157° oiled/varnished

Oak Thermo 157° varnished Evo / E-Matt

Oak Thermo 175° oiled/varnished

Oak Thermo 175° varnished Evo

Thermo Oak

Teak

Teak oiled / varnished

Teak varnished Evo

Teak varnished E-Matt

Teak

Wengé

Wengé oiled / varnished

Wengé varnished Evo

Wengé

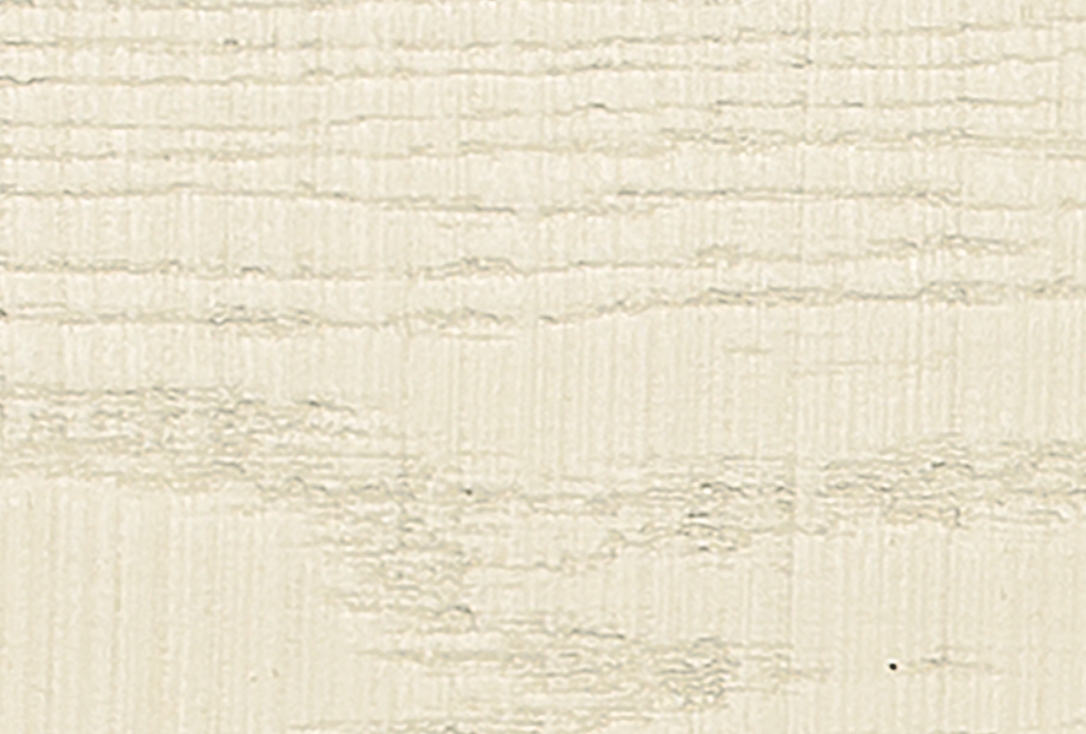

Thermo Ash

Rustic Ash Thermo 175° oiled / varnished

Rustic Ash Thermo 175° oiled velato bianco

Rustic Ash Thermo 175° varnished Evo

Thermo Ash

Pre-sanded

Pre-sanded

Brushed

Brushed

Taglio sega (saw cutting)

Taglio sega (saw cutting)

Taglio sega (saw cutting) 8 Color

Taglio sega (saw cutting) 8 Color

Hand-planed

Hand-planed

Stone

Stone

Hills

Hills

Irregular bevel

Irregular bevel

We take care of your parquet.

Our floors are made of high-quality wood and durable materials. They are intended to last a lifetime. In order to preserve their beautiful appearance over time and to keep the beauty of wooden surfaces intact, we offer a range of specific products for parquet care. They are designed to effectively and gently simplify the cleaning process.